Results 1 to 10 of 12

-

01-11-2016, 07:59 PM #1

Banned

Banned

- Join Date

- Jul 2015

- Location

- Fort Washington PA

- Posts

- 360

FABSPEED MOTORSPORT | Behind the Performance

We’ve been wanting to start an ongoing thread of all things Fabspeed: who we are, what we do, and what we build.

Fabspeed Motorsport is a precision machine shop, tuner, and manufacturer of performance products for exotic cars, located in a 26,000 square foot facility in Fort Washington, PA.

We are a team of passionate of over fifty automotive enthusiasts and craftsmen constantly working towards excellence. We proudly offer a wider selection of performance products for exotic cars than any other competitor in the industry with over a thousand different products and configurations.

Our knowledge depth, experience, and passion allows us to custom-tailor personalized performance solutions that perfectly complement the lifestyle and goals of every exotic car enthusiast. Sound, look, and service the way you want it. Our team of performance specialists are standing by to help you discover, understand, and exceed your automotive goals.

We look forward to updating this thread with interesting content on a regular basis. Posts will range from notable projects that come through the shop, to extracurricular activities like racing, technology, and much more. Subscribe and stay tuned!

Thread Directory:

Fabspeed History (Soon)

Shop Cars (Soon)

About Us (Soon)

Heavy Machinery (Soon)Last edited by Fabspeed_Motorsport; 01-25-2016 at 08:39 PM.

-

01-11-2016, 09:35 PM #2

Registered User

Registered User

- Join Date

- Sep 2014

- Location

- New Jersey

- Posts

- 519

The one thing I must say is that when I visited the shop for the open house it did look as clean as it did in those pictures. Certainly something I was surprised at.

Sent from my iPhone using Tapatalk2015 Lamborghini Huracan LP-610

2011 Ferrari California (SOLD)

1954 Corvette

-

01-18-2016, 10:41 PM #3

Banned

Banned

- Join Date

- Jul 2015

- Location

- Fort Washington PA

- Posts

- 360

FABSPEED MOTORSPORT | Shop Tour

SHOP TOUR

If you’re local to the Philadelphia area or traveling through, we encourage you to stop by and check out our shop. For our friends in other areas, we hope you’ll join us on this brief virtual tour of the Fabspeed Motorsport facility!

Welcome to our 26,000sqft headquarters and manufacturing facility located just outside of Philadelphia, PA!

The cars in the showroom are always cycling, but you can count on there always being some very impressive machinery on-hand.

Make yourself at home as we work on your vehicle. Relax, handle business, or chat with our tuner before grabbing lunch with your dedicated Performance Specialist.

This where the wrenches turn and the magic happens. At any given time we have a wide variety of different vehicles in for research and development as well as in-house installations and upgrades. We can install, develop, and build components for any exotic or high-end sports car, from McLaren’s to BMW’s.

We have a separate office in the shop which is home to our R&D team and recently expanded customer service department.

Our Unison all-electric CNC Mandrel Tube Bender, Haas CNC Machining Centers, Bystronic Press Brake, and Flow Waterjet are at the heart of our product manufacturing capabilities. We’ll post more information about our precision manufacturing division in our next post to showcase all the tools and equipment that we work with.

The Fabspeed Dynojet: fresh tunes served daily.

In our next post, we’ll dive into some of our R&D and fabrication processes in greater detail.

Keep an eye out for our annual Open-House events where we bring together the local exotics community for a full day of shop tours, dyno demos, and exotic cars glistening in the sun!

Metal, machinery, and sparks coming soon. Stay tuned!Last edited by Fabspeed_Motorsport; 01-18-2016 at 10:49 PM.

-

01-18-2016, 11:44 PM #4

Very impressive, keep up the good job.

2015 Verde Mantis Lamborghini Huracan

-

01-19-2016, 12:55 AM #5

Registered User

Registered User

- Join Date

- Sep 2014

- Location

- New Jersey

- Posts

- 519

The open house was a good time

Sent from my iPhone using Tapatalk2015 Lamborghini Huracan LP-610

2011 Ferrari California (SOLD)

1954 Corvette

-

01-19-2016, 01:08 AM #6

Somehow it looks familiar

-

02-03-2016, 09:05 PM #7

Banned

Banned

- Join Date

- Jul 2015

- Location

- Fort Washington PA

- Posts

- 360

FABSPEED MOTORSPORT | History

At the very core of our business is our development and manufacturing division. Thankfully, our team is comprised of some of the best minds in the business with access to cutting-edge technology and machinery.

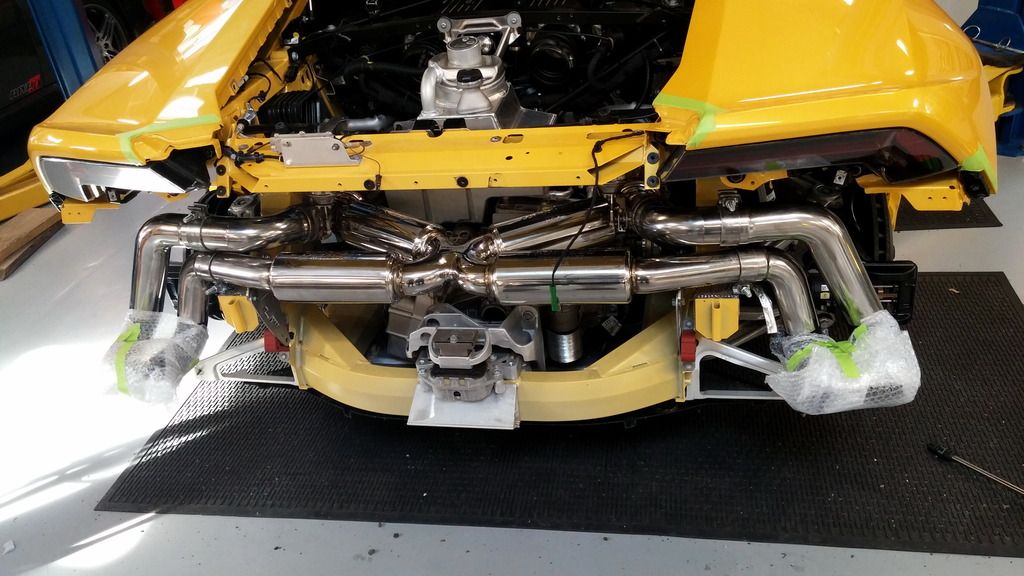

A perfect example of that technology is our 7-axis Romer CMM Digitizing Arm. This highly precise 3D scanning tool allows us to map out the exhaust tunnel and tubing bends of each new product that we develop, along with various mounting points, brackets, and more.

3D-digitizing and CAD designing components assists us both during and after the initial development period. We are often asked to make special alterations for customers with aftermarket body kits, track-oriented race setups, and other conditions which warrant unique and additional engineering changes. This data is also invaluable when it comes time to utilize our CAD-driven CNC equipment for the production of precision components.

Our Dimension Elite Additive Manufacturing Center (3D printer) has outstanding resolution and makes quick work of many of our prototypes. A prime example is our cast x-pipe which we incorporate into many of our products. This component began life as a digital concept, and went through many different 3D-printed variations before we found the optimal configuration for maximum flow performance. We also 3D-printed quality control gauges and jigs to ensure proper gap fit of our McLaren Supersport X-Pipe Exhaust System with both factory catalytic converters and our HJS-equipped Sport Cats.

The beating heart of our manufacturing facility is our Unison Breeze all-electric CNC mandrel tube bender It is capable of bending tubes up to 76mm (3 inch) in diameter as tight as a 1D radius, and pumps them out quickly and efficiently.

The Bystronic Xpert 150-ton press brake is a top-of-the-line sheet bender and looks the part. It is one of the only press brakes available that doesn’t produce angle errors and is known for having the highest repetition accuracy on the market. This baby makes quick work of our brackets, heat shields, mounting tabs, and more.

No, it is not a hot tub. That is our Flow Mach 4 XD-Series dynamic waterjet cutting station, which uses an 80,000psi stream of water and garnet to carve through metal like butter. A 6 foot x 12 foot cutting table allows for a wealth of production options. This bad boy can achieve tolerances as tight as 0.002 inches and has the capability to cut through up to 6 inches of solid steel. We use it to cut out everything from flange blanks to our carbon fiber marque wall art signs.

We utilize two HAAS CNC machines: a VF-2 vertical CNC mill and an ST-20 CNC Turning Center. These sister systems create our custom flanges; countersinking, drilling, and milling within 10/1000ths tolerance for a leak free seal. It may be more cost effective to purchase pre-made flanges, but we prefer to maintain full control over the components we produce with the ability to make alterations at a moments notice.

Our VF-2 vertical CNC mill boasts a 30 inch x 16 inch x 20 inch (762 x 406 x 508 mm) capacity, 40-degree taper, a 30hp (22.4 kW) vector drive which spins up to 8100 rpm, 20-station tool changer carousel, and a 55-gallon coolant circulation system.

We use our RMI UF-50 laser engraver to mark components with left and right annotations, and even offer a personalization service to really make our parts your own!

All of the fancy machinery on the planet wouldn’t do us any good without our team of highly-talented machinists and fabricators. Our specialists are trained to manipulate metal with all manner of tools and technology.

Check out some of our team and equipment in action in our How It Is Made video, which shows the various processes involved in manufacturing our world-famous Porsche Turbo Supersport Exhaust Systems!

Thank you for taking the time to learn about our manufacturing. Next up we'll dive into the origins of Fabspeed and how we’ve grown over the decades.Last edited by Fabspeed_Motorsport; 02-03-2016 at 09:25 PM.

-

02-04-2016, 11:18 AM #8

-

02-04-2016, 03:37 PM #9

Banned

Banned

- Join Date

- Jul 2015

- Location

- Fort Washington PA

- Posts

- 360

-

02-04-2016, 04:06 PM #10

Registered User

Registered User

- Join Date

- Jun 2015

- Location

- Florida

- Posts

- 166

Phenomenal video.

Cant wait to see read the origins and early day of fabspeed.2018 Huracan Performante arancio borealis, HRE P101

2018 991.2 GT3 Sapphire blue metallic IPE Titanium Exhaust, HRE R101LW

2015 Mercedes S63 AMG Coupe - HRE P204

2016 Mercedes S550 Coupe - Matte white

Reply With Quote

Reply With Quote

Bookmarks